Alumna Lindsay Erickson on the UCLA Margo Leavin Graduate Art Studios

Dec 9, 2019

Designed by the Los Angeles-based architecture firm Johnston Marklee, the award-winning UCLA Margo Leavin Graduate Art Studios is a world-class facility dedicated to supporting emerging artists and strengthening Los Angeles’s position as a world arts capital.

Lindsay Erickson ’10 (UCLA Architecture and Urban Design) is a senior associate at Johnston Marklee and served as project lead for the UCLA Margo Leavin Graduate Art Studios. On the occasion of the first public opening for the building, Lindsay shared a few insider details about the project.

Artist-Centric Design

I received my Masters of Architecture from UCLA AUD and spent a lot of time in Perloff Hall on the UCLA campus. While the graduate architecture studio culture is different from that of the graduate art program, my time at AUD definitely helped me understand how important it is for students to have agency over their personal studios and the building.

In the new UCLA Margo Leavin Graduate Art Studios, you can really see the feedback we got from students and faculty during the design process come to life in the three covered out-door spaces: our original concept design had a large covered arcade that ran from the parking on the north all the way to the corner of Warner Drive on the south. But when we heard from the students and faculty about how they make work in the studios, we changed the design and created three high-bay, open-air covered work yards—the entry garden, sculpture yard, and ceramics yard—to accommodate the specific needs of the artists while taking advantage of the temperate Southern California climate.

If I were a student, I would definitely want to spend most of my time in the covered yards, especially the garden or the sculpture yard. The way the light transmits through the polycarbonate roof means that there are no shadows, which gives the spaces a serene atmospheric quality.

Conservation

All of the rainwater that falls on the roof of the new building is collected and distributed to an underground storm water infiltration tank located below the parking spaces on the north side of the building. The large manhole cover near the accessible parking space provides access to the infiltration tank. Recognized for its exceptional sustainable design with a Lafarge Holcim Award, stormwater retention is just one of the many design strategies that the architects integrated into the building.

Hanging Out

Check out the cantilevered concrete! As you come through the main entry of the building, look up and you will see two concrete cantilevers measuring 40 ft. along the Hayden side and 24 ft. along the north side of the entry. If you pay close attention, you’ll notice that those concrete masses appear to be floating freely. It took some serious structural gymnastics to pull this off!

Light + Space

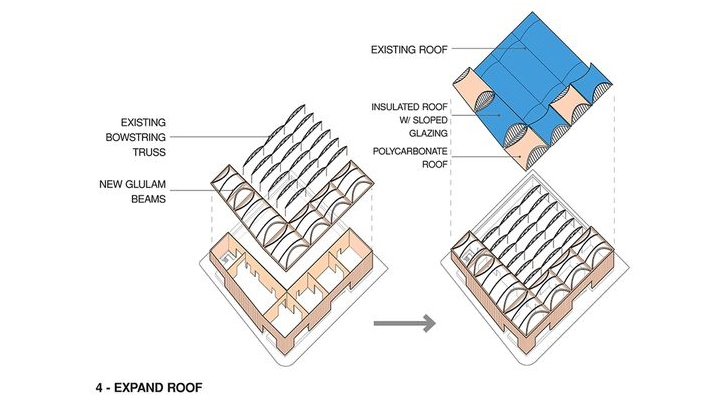

While the details of the polycarbonate roof over the entry garden and covered yards are quite simple, the application of the poly-carbonate is not. There are three different types of polycarbonate that make up the roof to reduce heat gain and glare: the south facing sloped polycarbonate has a gel infill that reduces heat gain, the north facing sloped polycarbonate is clear allowing a view to the sky above, and the main barrel vault polycarbonate is translucent to mitigate shadows and glare while allowing natural light to filter into the space.

Reinterpreting Form

The geometry of the new roof is, for me, the most interesting and innovative aspect of the design. The roof of the original building is comprised of bow-string trusses that we kept intact. The new roof structure is our interpretation of the bowstring truss: a typical bowstring truss has a lot of complicated geometry to negotiate where the roof meets the walls. We simplified the geometry by eliminating the trusses double curvature, which allowed us to have the large, flat, arched-shaped skylights on the north and south ends of the new roof.

Hidden History

While the site was being excavated to make way for the building’s new foundations, two metal tanks were found about three feet below the asphalt, one of which had gasoline inside!

Concrete Details

There are three different types of concrete in the new portion of the building: 1.The walls that separate the new structure from the original structure are made of shotcrete, a type of concrete that is shot vertically onto ‘forms’ out of a big hose. You can distinguish shotcrete from other types of concrete because it is troweled smooth; 2.The undulating, pillow shaped exterior walls facing the street are tilt-up concrete. Characteristic of many industrial buildings in the area, tilt-up concrete is poured into trays, or molds that give them their shape, on site and then is tilted up vertically in place; 3.You can find the third type of concrete, cast-in-place, on the interior walls that divide the spaces, such as between the covered yards and the workshops. Cast-in-place is made by constructing plywood forms into which concrete is poured from above and then, once the concrete is set, remove the forms leaving the surfaces with their distinctive markings. If you look closely at cast-in-place walls, you will see a trace of the forms that once were – an ever-present artifact of the fabrication process.

Thermal Details

The concrete walls are a minimum of 10” thick. Since we live in LA, no additional insulation was needed for the walls: the mass of the concrete is doing all of the work!

Power Down, Walls Up

To avoid any conflicts with the overhead high voltage transmission lines during the tilt-up process, the local utility, Southern California Edison, had to shut down and reroute power along Hayden Avenue. So, the team really needed to work fast and erected all but one of the tilt-up wall panels in only three working days (and all those along Hayden in just two)!

This article was reposted from the UCLA School of Arts and Architecture's 100 for 100 - a collection of stories that celebrate the rich history of the arts at UCLA over the past century. Read more at 100.arts.ucla.edu.